OneCNC at TechniShow 2016

OneCNC Benelux exhibited at TECHNISHOW 2016 in Utrecht 15-18 March 2016

The TechniShow is hosted at the Jaarbeurs centre in Utrecht Netherlands.

TechniShow is the largest and the most important expo in Benelux that is concerned with industrial production technology, processing, treatment and metal tool and appliances. This event was run for a period four days and focused primarily on business and created an ideal platform to meet the entire industrial chain and establish new contacts and business leads. TechniShow was again held together with the ESEF show of manufacturing exhibitors and both these events provided a great opportunity for the production sector. This excellent event helped the exhibitors get acquainted with professional of the industry and it was reported that more than 40,000 visitors attended the event..

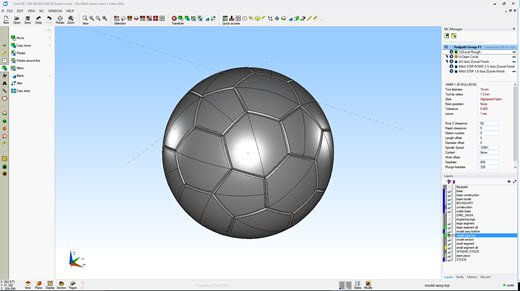

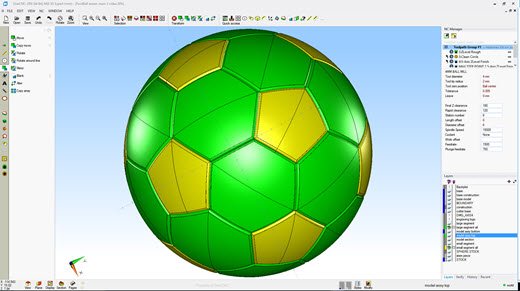

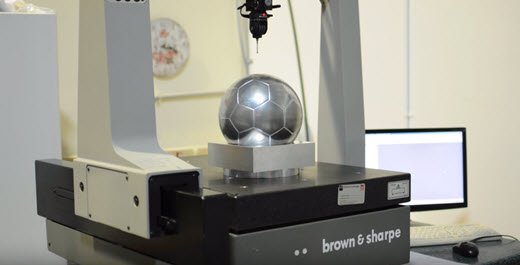

OneCNC Benelux with experienced application engineers were provided with a very busy platform to demonstrate the unique advantages of the OneCNC products.

Each of the 4 days were very busy demonstrating to new potential customers as well as product discussions with existing customers.

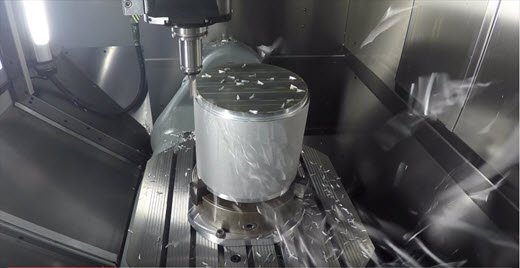

OneCNC is very popular in Benelux and it was well noticed that OneCNC products were actively shown and used on machines in action at the show .

One of the main reasons OneCNC is so popular in Benelux is that OneCNC has experienced application engineers that can assist both the machine tool application engineers as well as train and assist the customers using the products providing a complete support structure for the OneCNC customer.

The TechniShow was very busy each day and if by chance you missed having a personal demonstration of OneCNC this can be arranged at your shop at a time to suit.

OneCNC Benelux has experienced engineers and covers the whole area of the Netherlands, Luxembourg and Belgium, provides full on-line or on-site training and full support of the entire range of OneCNC products. So if you are in the business of CNC manufacture call OneCNC Benelux for professional attention to your requirements.

For further information on OneCNC products in Benelux contact OneCNC Benelux >> www.onecnc.nl

OneCNC Benelux

Mierloseweg 40

5666 KA Geldrop

The Netherlands

ph:+ 31 (0) 40 22 66 212

fax:+ 31 (0) 40 22 40 794

OneCNC Updates

OneCNC XR9 Release 74.83

Apr 23 2024

OneCNC XR9 Release 74.80

Apr 01 2024

OneCNC XR9 Release 74.77

Feb 28 2024